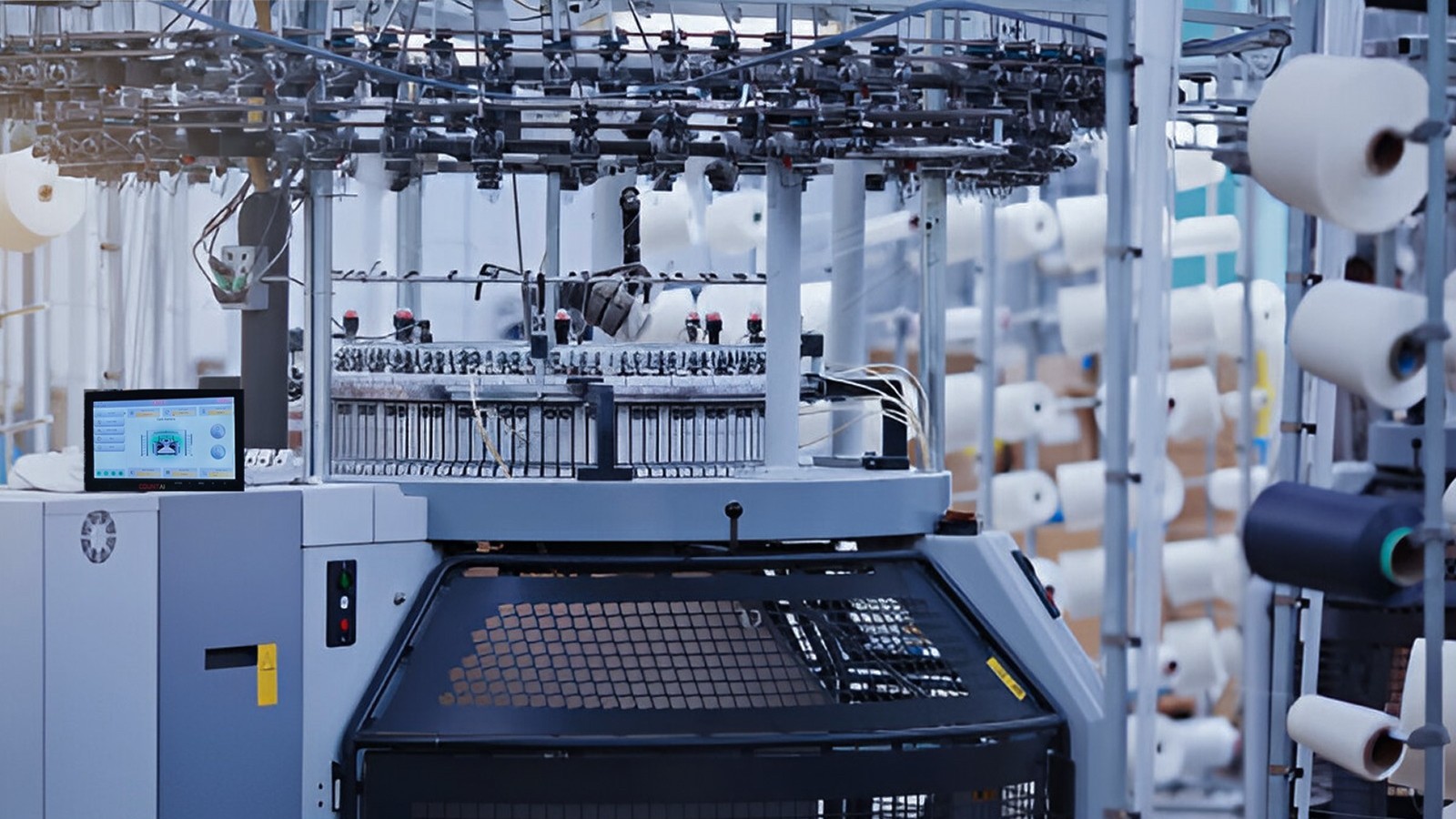

Transforming Textile Manufacturing with AI‑Driven Precision

Achieve zero‑defect circular‑knitting, optimise OEE and elevate quality with real‑time vision.

- Home

- Textile

Challenges

Manual fabric inspection is slow and prone to human error.

Variations in yarn tension and elastane slippage cause defects.

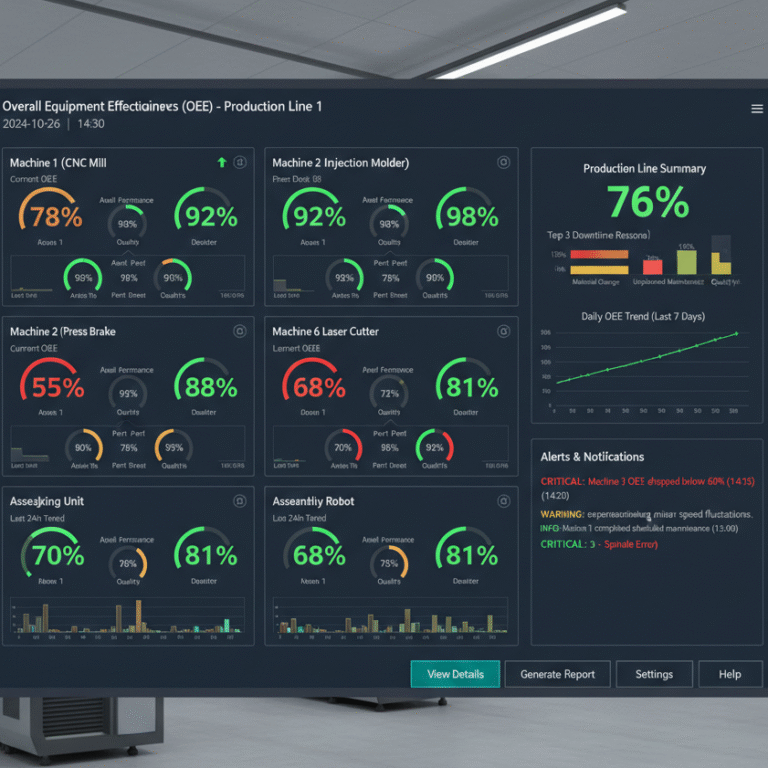

Tracking Overall Equipment Effectiveness (OEE) across multiple machines is difficult.

Our Solutions

AI‑Powered real-time Defect Detection: Deep‑learning models identify yarn density variations, needle lines, holes, oil stains and elastane issues in real time.

Automated Control: If defects are detected, necessary steps are taken automatically by Knit-I

Management Dashboard: To get the key insights to run textile factory error-free with much higher productivity

Benefits

Zero‑Defect Production

Real‑time inspection eliminates fabric defects and reduces rework.

Increased Efficiency

Operators focus on high‑value tasks; labour requirements drop by more than 90 %.

Reduced Downtime

Predictive maintenance cuts unplanned stoppages by up to 50 %.

Data‑Driven Decisions

OEE reports help managers schedule maintenance, optimise machine settings and improve yield.

Service Group

Why Choose CountAI for Your Textile Operations?

Enhanced Fabric Consistency

Maintain uniform texture and color across production batches with intelligent monitoring.

Automated Defect Alerts

Instantly detect anomalies and notify operators to prevent defective fabric from progressing further.

Process Optimization

Streamline production workflows by analyzing machine and material performance data.

Cost Efficiency

Minimize resource usage and downtime, leading to lower operating expenses and higher profitability.

Scalable Solutions

Adapt our AI systems to meet the needs of small units or large-scale textile plants.

Operator Assistance

Support your workforce with AI tools that guide and improve daily tasks without adding complexity.

Data-Driven Quality Reports

Generate comprehensive reports that track performance trends and highlight areas for improvement.

Compliance & Traceability

Ensure manufacturing standards are met and maintain complete traceability for audits and certifications.

Case Example

A leading knitwear manufacturer deployed CountOnAI’s Knit‑i Insight across 40 knitting machines. Within three months, defect rates fell by 35 % and first‑pass yield increased by 30 %, allowing the company to meet international quality standards and reduce waste.”