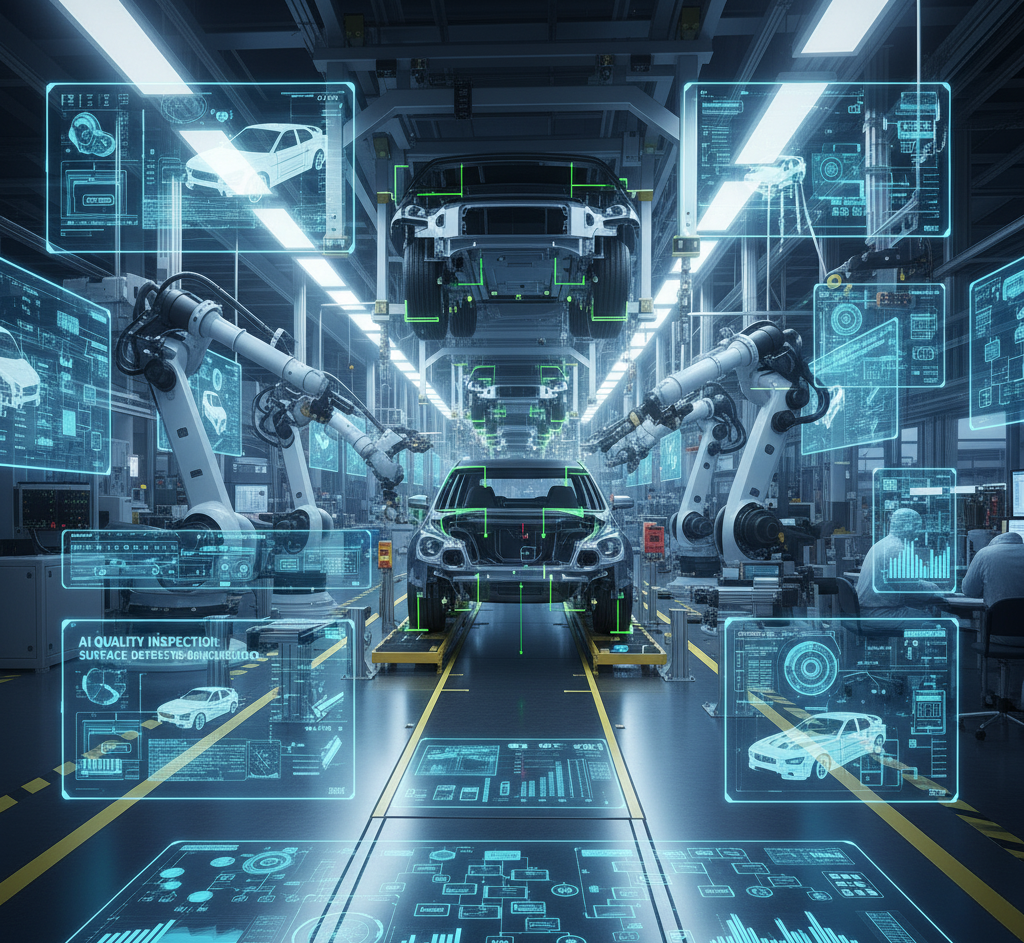

Driving Automotive Quality with AI‑Enabled Vision Systems

Ensure flawless assembly, perfect paint finishes and traceable records on every vehicle.

- Home

- Automobile

Challenges

Automotive

Industry Challenges

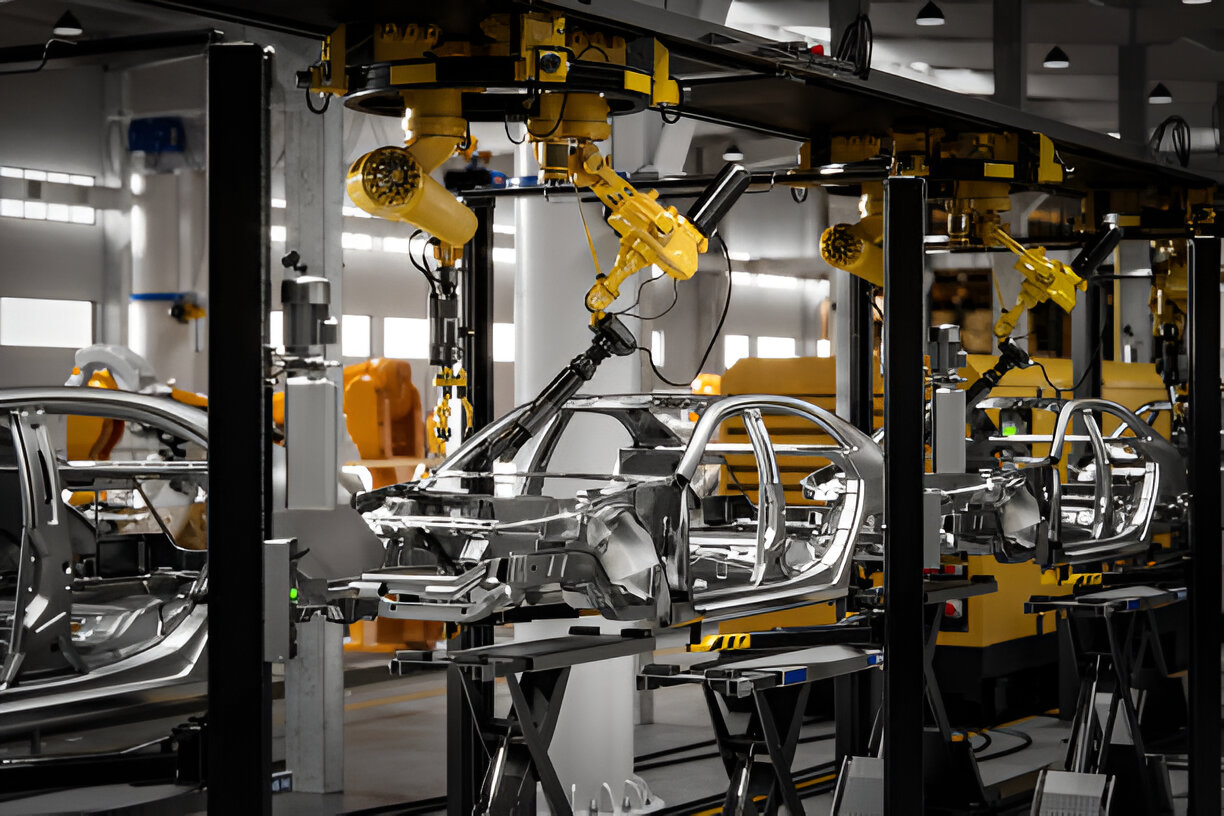

- Thousands of components and welds require precise verification.

- Paint defects (scratches, bubbles) harm brand reputation.

- Robots and conveyors can break down unexpectedly, halting the line.

Our

Solutions

Component & Assembly Inspection:

Vision ensures nuts, bolts, clips and wiring harnesses are present and correctly installed.

Weld & Solder Quality:

AI analyses weld seams for gaps, porosity and misalignment.

Paint & Surface Inspection:

Detects scratches, dents, dust and orange‑peel texture.

Gap & Flush Measurement:

Cameras measure panel gaps to sub‑millimetre accuracy.

Predictive Maintenance for Robotics:

Monitors motor currents and temperature to prevent unexpected robot failures.

Traceability:

Captures images and data at every stage, supporting recalls and root‑cause analysis

Benefits

Fewer Recalls:

Early defect detection prevents defective vehicles from leaving the factory.

Higher Throughput: Less rework and downtime

(downtime cut by 50 %, maintenance costs by 25 %).

Improved Brand Reputation: Consistent quality and finish.

Actionable Insights: Real‑time dashboards for supervisors.

CountAI: Driving Automotive Excellence with AI

Industry-Leading Expertise

From concept to delivery, we provide end-to-end AI solutions designed to meet the unique challenges of the automotive sector—driving smarter, safer, and more efficient operations.

Proven Results, Real Impact

Our AI technologies deliver measurable improvements—boosting production efficiency by up to 20% and drastically reducing defect rates for superior quality.

Relentless Innovation

We stay ahead of industry trends, integrating cutting-edge AI advancements to keep your operations future-ready and competitive.

Scalable, Tailored Solutions

No matter your size or complexity, our flexible solutions are customized to fit your business, helping you scale seamlessly and stay agile.

See how we improve your line’s first‑pass yield.

Discover how our cutting-edge solutions deliver expert-driven results across industries—from automotive advancements to renewable energy initiatives.